Abstract

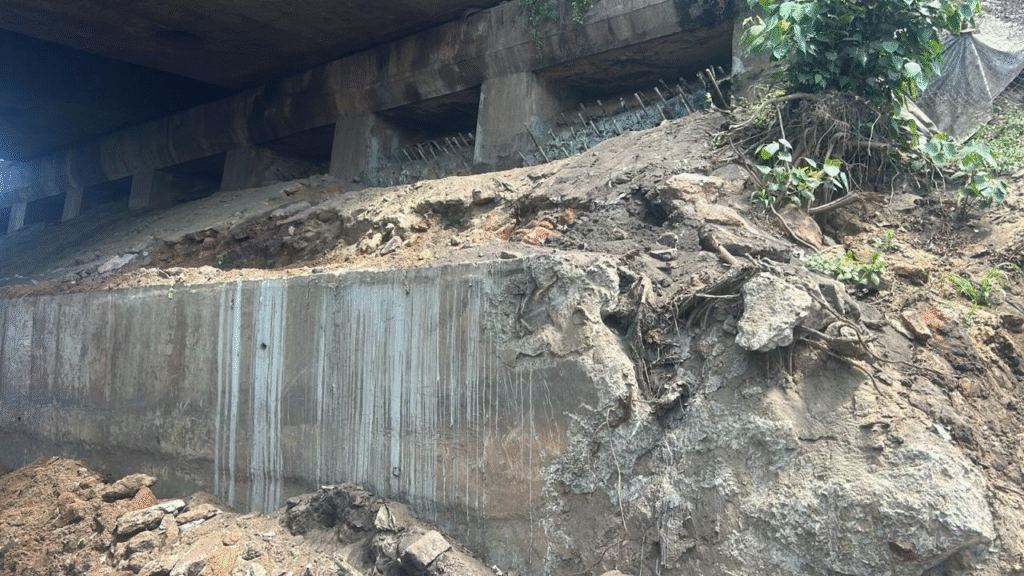

At Jindal Paradip Port, Odisha, a major infrastructure challenge arose during the expansion of railway facilities beneath an existing Road Over Bridge (ROB). The retaining wall was directly supporting the soil of the bridge abutment. If it collapsed, it would have stopped all railway and vehicular movement into the port, leading to massive operational disruption.

To accommodate the laying of an extra railway lane, it was necessary to dismantle an old structural wall filled with marine sand, within highly constrained site conditions.

Initial stabilization attempts using soil nailing services failed due to severe sand collapse, endangering workers and risking disruption to both port traffic and railway operations. Further complexity arose from the limited 3 m headroom under the ROB, which made conventional piling equipment unusable.

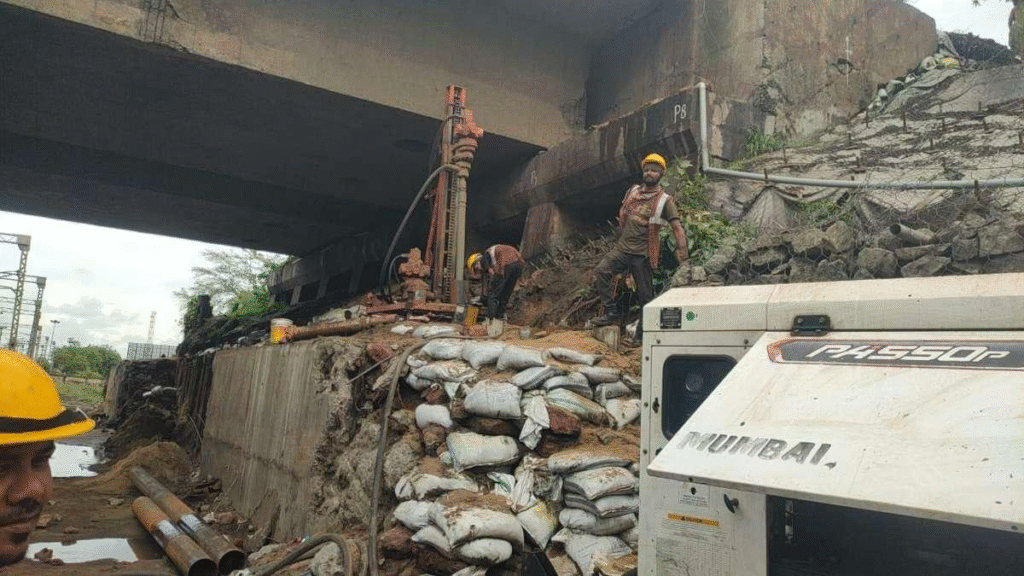

This case study presents how Savinaya Infratech Pvt. Ltd. not only prepared the design and drawings but also executed the works using a combination of ODEX Micropiling (9.5 m steel casings, total 10 m depth), a custom-designed low-mast (2.5 m) drilling rig, staged casing welding, Geocomposite, stone pitching, and Shotcreting.

The adopted system ensured safe dismantling, stabilized the foundation zone, and successfully created the additional space required for the new railway lane while maintaining uninterrupted traffic and port operations.

How ODEX Micropiling Enabled Safe Railway Expansion at Paradip Port

The expansion of rail infrastructure in congested operational areas demands innovative geotechnical solutions. At Paradip Port, a critical requirement was to lay an additional railway lane beneath the existing ROB, which served as the only entry point for both trains and vehicles to the port. This was particularly critical because the retaining wall was holding the soil of the bridge abutment and any collapse would have halted both rail and vehicular movement into the port.

Conventional soil nailing methods proved unsuitable, as loose marine sand backfill caused dangerous collapses during wall dismantling. Moreover, the restricted 3 m clearance beneath the ROB eliminated the option of using standard piling rigs.

This case study highlights how ODEX Micropiling services with custom low-mast drilling equipment, staged casing installation, Geocomposite, stone pitching, and shotcrete facing was successfully applied by Savinaya Infratech to overcome these challenges and enable safe space creation for the additional railway lane.

Project Background

- Client: Jindal Paradip Port Ltd

- Location: Paradip Port, Odisha, under the existing ROB.

- Objective: Create safe and stable space to lay an additional railway lane.

- Constraints:

- Loose marine sand backfill behind the retaining wall, prone to collapse.

- Only 3 m headroom available, restricting the use of conventional rigs, with limited space for platform to place the machine.

- Drilling Micropiles through the retaining wall foundation to achieve pile alignment.

- Operational continuity required: collapse could halt both train and vehicular traffic to the port.

- Safety Incident: During soil nailing process, sand collapsed suddenly up to labour’s neck level, creating a life-threatening situation. This forced suspension of works and emergency stabilization with gabions and nails.

Savinaya’s Intervention

The Savinaya team prepared the complete design and drawings and proposed ODEX Micropiling with Geocomposite, shotcrete, and stone pitching as the permanent solution.

Key methodology highlights:

- Custom Drilling Rig: Developed a compact rig with a 2.5 m mast to operate under the 3 m clearance of the ROB.

- Staged Casing Welding (Headroom Constraint Solution):

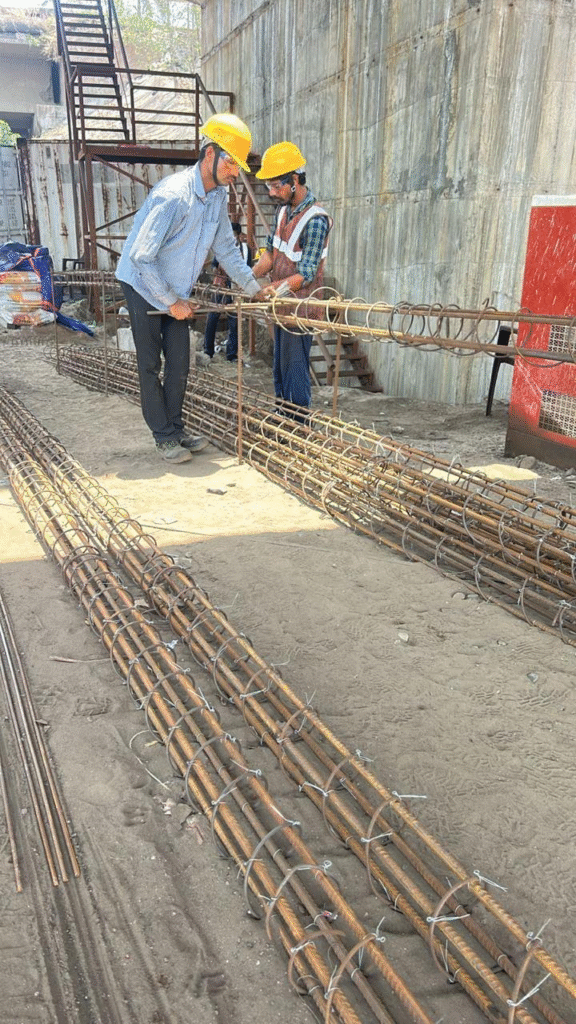

- ODEX Micropiling: 4 mm thick steel casing piles were installed, reinforcement cages inserted, and piles concreted as per design.

- Geocomposite Placement: Installed between Micropiles and backfill to act as a drainage and separation system, preventing marine sand erosion and enhancing wall performance.

- Controlled Dismantling:

- Initially, sandbags were kept ready as a precautionary measure to support the marine sand during dismantling.

- After Micropiles were secured, the retaining wall was carefully dismantled in layers.

- Dismantling the gabion wall was done 2 m at a time, with sandbags and geotextile sheets placed behind the gabion wall to stabilize the marine sand.

- Final Structural System:

- Welded wire mesh + shotcrete layer provided initial stabilization after dismantling.

- Casing extensions (0.5 m), welded cages, and final concreting ensured pile continuity.

- A pile cap beam was cast to tie all Micropiles.

- Stone pitching behind Micropiles + final shotcrete facing ensured erosion protection and long-term durability.

Execution Challenges & Safety Measures

- Sand collapse during soil nailing highlighted the instability of marine backfill.

- Restricted clearance was overcome by fabricating and welding 2 m casing sections.

- Worker safety ensured through supervised staged dismantling with scaffolding, barricading, and protective measures.

- Drilling through foundation concrete and reinforcement below 2.5 m required specialized equipment and precise execution.

Results & Observations

- All Micropiles (10 m depth) were successfully completed using 2 m casing sections welded progressively despite space restrictions.

- Retaining wall dismantled safely after Micropiles were installed, without causing sand collapse.

- Geocomposite + Stone pitching + Shotcreting provided a multi-layered protective system against erosion and backfill movement.

- No movement of piles was observed even after complete dismantling of both the retaining wall and gabion wall.

- Space for the new railway lane was created safely without interrupting port traffic.

- Client commended Savinaya for its design ownership, execution strategy, and safe delivery under extreme constraints.

Discussion

- Soil nailing is unsuitable in loose marine sand environments.

- ODEX Micropiling with staged casing welding provides a reliable solution under headroom restrictions.

- A hybrid stabilization system (Micropiles + geotextile + Geocomposite + wire mesh + shotcrete + stone pitching) ensures long-term safety and durability.

- The design + execution ownership by Savinaya Infratech was key to success.

Conclusion

The Jindal Paradip Port project demonstrates how ODEX Micropiling with staged casing welding can be applied to create space for new railway lanes in highly constrained marine environments. Savinaya’s integrated design, drawings, and execution enabled the safe installation of 10 m Micropiles, controlled dismantling of the old retaining wall and temporary gabion wall, and construction of a durable stabilization system using Geocomposite, stone pitching, and shotcrete.

This project highlights the value of adaptive engineering and innovation in equipment, sequence, and materials for critical transport infrastructure.